For nearly two decades, American shipyards have operated under a quiet but dangerous assumption: that the security standards written in the aftermath of 9/11 somehow remained fit for a modern threat environment defined by unmanned systems, AI-enabled reconnaissance, cyber-surveillance, and increasingly sophisticated nation-state competitors. It was a comforting assumption, and an incorrect one.

The 2025 National Security Strategy does not state this outright, but it doesn’t have to. Its language is clear: the maritime industrial base is now a strategic target, and our adversaries view the seams in our domestic infrastructure as opportunities, not obstacles. Washington hardly needed to remind anyone who works inside a naval shipyard; the evidence has been mounting in plain sight.

Private repair yards such as BAE, NASSCO, Austal, Fincantieri, Vigor, Detyens, Philly Ship Repair, and dozens more are doing the hard, unglamorous work of keeping the fleet alive. These yards touch everything from DDGs to LCS hulls to MSC logistics vessels. They are indispensable. But unlike public naval shipyards, they operate under a fragmented regulatory structure: NAVSEA 009-72 written for an earlier era, MTSA compliance written for an even earlier one, and uneven implementation across regions or prime contractors.

Security under these conditions becomes something dangerously close to “best effort.” And “best effort” is nowhere to be found in the National Security Strategy’s description of what the United States must now be capable of.

The reality is simple: the requirements have outgrown the rulebook.

A Threat Profile the 009-72 Never Considered

When the USS Cole was attacked in October 2000, the world saw what a determined adversary could do with a small boat, patience, and the element of surprise. Twenty-five years later, the threat environment has evolved radically, but the operational guidance for protecting naval vessels inside private shipyards has not evolved with it.

We now live in a maritime security landscape defined by:

• Low-cost unmanned surface vessels capable of long-range reconnaissance or kinetic employment

• Commercially available thermal optics, night vision, and side-scan sonar that adversaries use as freely as commercial fishermen

• Cyber breaches enabling real-time vessel movement tracking

• Criminal or extremist activity around high-value infrastructure zones

• An increasingly congested waterfront where local law enforcement, Coast Guard, harbor pilots, contractors, and commercial operators compete for access and priority

These are not hypothetical scenarios. NAVSEA, MARAD, and DHS have been warning about them for years; the NSS just places them at the center of national strategy.

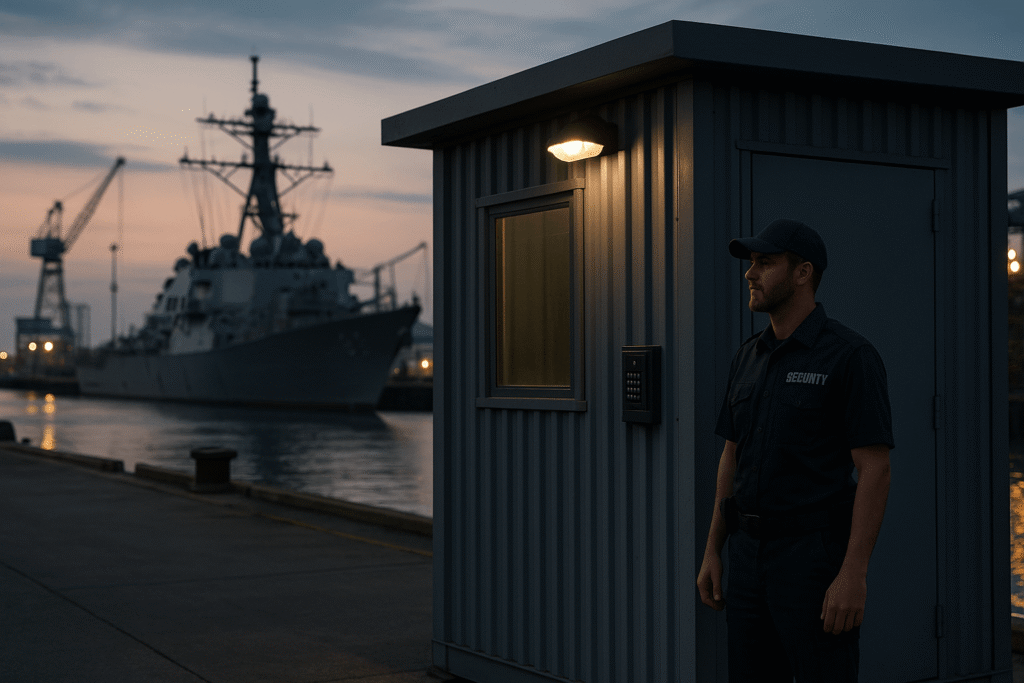

Yet at many private shipyards, vessel protection zones remain static, manpower-driven, analog, or inconsistently enforced. In some locations, contracted guard forces lack standardized training, lack waterborne mobility, and lack even the basic awareness of how a threat would present itself in 2025.

Put bluntly: today’s threat environment is modern. Too much of the protection architecture is not.

Why This Matters Now, The NSS Makes It Explicit

The National Security Strategy’s language is unusually direct for an administration document:

- “The resilience of the maritime industrial base is a matter of strategic deterrence.”

- “Critical infrastructure at the seams of federal and commercial responsibility must be fortified.”

- “Public-private integration is no longer optional to sustain forward warfighting capacity.”

Whether intended or not, this is a direct indictment of the status quo.

For the first time, the White House is stating what operators, shipyard supervisors, and waterfront security managers have known for years: our adversaries are not coming after warships at sea; they are coming for them while pierside, under repair, and at their most vulnerable.

A disabled destroyer in dry dock is a strategic gift to any peer competitor. Chaos at a private repair facility creates headlines that reverberate through Congress, through appropriations committees, through allied navies, and through global shipping markets.

We do not need to imagine the consequences as the Navy has lived them before.

Where the Gaps Live

When you strip the problem down to its elements, three gaps stand out:

1. No unified national standard for contracted shipyard security

Every shipyard we work with, West Coast, East Coast, Gulf Coast, Pacific Northwest, interprets security requirements in a slightly different way. Some exceed the NAVSEA standard; others simply meet it; many operate in the gray space created by subcontract layers, cost pressures, and local practices.

2. No operational integration between physical security, technology, and maritime domain awareness

DHS, the Navy, and the NSS all emphasize integrated MDA, but at many yards, patrols are still conducted with handheld radios, limited optics, and no sensor fusion. Threat detection becomes reactive rather than anticipatory.

3. No clear budgeting authority

Public shipyards have appropriated security budgets. Private shipyards rely on primes, subcontractors, or ambiguous contract language. When security becomes a line item rather than a requirement, it becomes the first place corners are cut. These gaps create vulnerabilities the NSS is now openly acknowledging, without naming the shipyards directly.

Where Six Maritime Fits — and Why This Matters Beyond Us

This isn’t a marketing slogan. It’s the truth: Six Maritime occupies the operational space the NSS describes but does not define.

We sit at the intersection of:

• NAVSEA 009-72 compliant waterborne security

• Shipyard operations where Navy assets are exposed

• Integration of autonomous systems, sensors, and AI-enabled maritime domain awareness

• Training pipelines that bring guard forces up to a 2025 threat standard

• Real-world operational experience at multiple shipyards across two coasts

The NSS is calling for a national architecture that blends human expertise + technology + private sector agility. That is exactly where Six Maritime’s POAM, BD strategy, and 2026 growth plan are pointed, not conceptually, but operationally, with live contracts, R&D partnerships, and deployed guard forces.